Enhance your manufacturing facility with Lifetime Green Coatings’ eco-friendly, high-performance concrete manufacturing floor coatings. Our durable concrete factory floor coatings are designed to withstand the heavy traffic and tough conditions found in industrial environments. Whether you’re dealing with forklifts, pallet jacks, or heavy machinery, our coatings provide long-lasting, low-maintenance protection for your floors. With our non-toxic, low-VOC solutions, you can create a safer, more durable workspace while preserving the integrity of your concrete floors.

Common Challenges in Manufacturing Facilities

Manufacturing and industrial facilities face unique flooring challenges that require specialized concrete floor coatings. Without the proper concrete floor coating systems for your manufacturing facility, your industrial floor may experience:

- Wear and Tear from Heavy Equipment: Constant exposure to heavy machinery, forklifts, and pallet jacks can cause significant damage to concrete floors, leading to scratches, cracks, and surface degradation. Our heavy-duty industrial floor coatings protect your facility’s concrete from damage, extending its lifespan and ensuring a professional appearance. In high-traffic areas, this added protection is critical for maintaining a safe and functional workspace, especially in zones where large machines and heavy loads are frequently transported.

- Chemical and Oil Stains: Factories often encounter chemical spills, oils, and other contaminants that can seep into porous concrete floors, creating stains that are difficult to clean.

Our non-porous, stain-resistant coatings prevent these substances from penetrating your concrete, making your floors easier to maintain. The coatings also act as a shield, preventing corrosive chemicals from damaging the structural integrity of your floors, which ultimately reduces repair costs and prolongs their life.

- Slippery Surfaces and Safety Concerns: Industrial facilities frequently deal with spills and moisture, leading to slippery, hazardous floors. Our anti-slip concrete floor coatings provide a safer environment by reducing the risk of slips and falls, ensuring your team can work safely, even in high-traffic areas. This added layer of protection is particularly important in spaces where liquid spills are common, enhancing safety protocols across the facility.

- Aesthetic Wear and Tear: Over time, untreated concrete factory floors can look dull and worn, reflecting poorly on your facility’s image. Our coatings provide a sleek, polished finish that enhances the overall aesthetics of your manufacturing space, creating a clean and professional environment. A well-maintained floor not only improves the appearance of your facility but also demonstrates a commitment to safety, cleanliness, and operational efficiency.

Why Choose Lifetime Green Coatings for Your Manufacturing Facility?

At Lifetime Green Coatings, we offer superior concrete floor coatings for manufacturing facilities that combine durability, protection, and eco-friendly innovation. Here’s why our industrial flooring solutions stand out:

- Durability and Longevity: Engineered to endure the heavy use of industrial floors, our coatings are built to last, protecting your facility’s concrete floors from the wear and tear of machinery, forklifts, and pallet jacks. With high scratch resistance and a durable topcoat, your floors will maintain their strength and appearance for years, even in the most demanding conditions. These coatings are ideal for areas exposed to heavy-duty equipment, ensuring they remain functional and aesthetically appealing for the long haul.

- Non-Porous, Stain-Resistant Surface: Our concrete floor coating systems form a non-porous barrier that resists oil, grease, and chemical spills. This makes clean-up fast and efficient, helping you keep your factory floors looking pristine and professional. The impermeable nature of our coatings prevents contaminants from seeping into the concrete, protecting your floors from long-term damage and reducing maintenance costs.

- Low Maintenance and Quick Installation: Our easy-installation, eco-friendly coatings are fast-curing, minimizing downtime and allowing your facility to return to normal operations quickly. Plus, they require minimal maintenance, so you can focus on production without worrying about your flooring. Whether you operate a large-scale factory or a smaller facility, our quick installation process ensures minimal disruption to your workflow, so you can continue business as usual with durable, reliable flooring beneath you.

Professional Installation for Concrete Floors in Manufacturing Facilities

At Lifetime Green Coatings, we pride ourselves on providing expert installation to ensure your concrete factory floor coatings are applied with precision for maximum durability:

- Thorough Surface Preparation: We meticulously prepare your concrete floors to ensure optimal adhesion and long-lasting performance of our industrial floor coatings.

- Precision Application: Our skilled technicians apply the coating with care, ensuring an even, high-performance finish across your entire facility.

- Fast Curing Technology: Our advanced coatings cure quickly, minimizing downtime so your production can resume as soon as possible, with minimal interruption.

Maintaining Your Factory Floors with Ease

Our concrete factory floor coatings make maintenance simple. Here’s how you can keep your floors looking their best:

- Routine Cleaning: Regular cleaning with mild soap and water will keep your concrete floors free from dirt, oil, and chemical residues. The non-porous surface of our coatings makes this task quick and easy.

- Periodic Inspections: Regularly inspect your industrial floors for signs of wear, especially in high-traffic areas. Early detection of any damage helps preserve the longevity of your concrete floors and coatings.

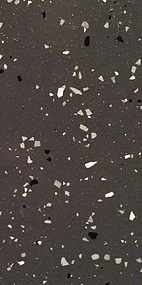

Floor Coating Color Samples:

Choose from a selection of solid colors or customize with your choice of colored flakes. Create a color coat that meets the aesthetic requirements of your client while also providing durability and protection.

Sinclair Silver

Jensen Steel

Bristol Brass

Sinclair Silver

Jensen Steel

Bristol Brass

Material Specifications:

Key Adhesion Numbers:

| Thickness | 0.050”-0.100” (1.3mm - 2.5mm) |

| Durability | Astm C627 [16,000 Passes Of An Average Sized Car] [No Debonding Or Deterioration Occurred] |

| Tensile Strength | Astm D412 900 Psi (20 mil application) 2000 Psi (35-40 mil application) |

| Elongation | Astm D412 20 - 100% |

| Crack Bridging | 1/16” (1.6mm) |

| Impact Resistance | (Izod) 2 Ft-lbsf/Inch ( Drops Sharply At -20°c ) (11 Kgf-mm/Mm) Hardness - Shore Durometer D 50 +/- 10 |

| Hardness | Shore Durometer D 50 +/- 10 |

| Heat Resistance | Continuous 200°f (93°c) |

| Minimum Temperature | -20 To -40°f (-30 To -40°c ) |

| Maximum Temperature | 200°f (93°c) |

| Water Absorption | Astm D570 0.3 % |

| Rapid Chloride Permeability | Astm C1202 17 (Nil) Coulombs [After 6 Hours] |

Why Lifetime Green Coatings is the Best Choice for Industrial Facilities

Lifetime Green Coatings offers a comprehensive floor coating solution that combines durability, chemical resistance, and safety for industrial facilities. Our eco-friendly, non-toxic concrete floor coatings for factories provide long-lasting protection against the intense wear of heavy-duty machinery and constant traffic while offering an attractive, polished finish.

By choosing Lifetime Green Coatings, you’re investing in flooring that’s not only built to last but also easy to maintain and environmentally responsible. Protect your industrial facility’s concrete floors from damage, enhance safety, and improve the overall appearance of your workspace. Request a free quote or find a location near you to get started.